Demand for sustainable fashion options is changing the industry, with a growing portion of shoppers seeking out brands that source, produce and recycle products responsibly.

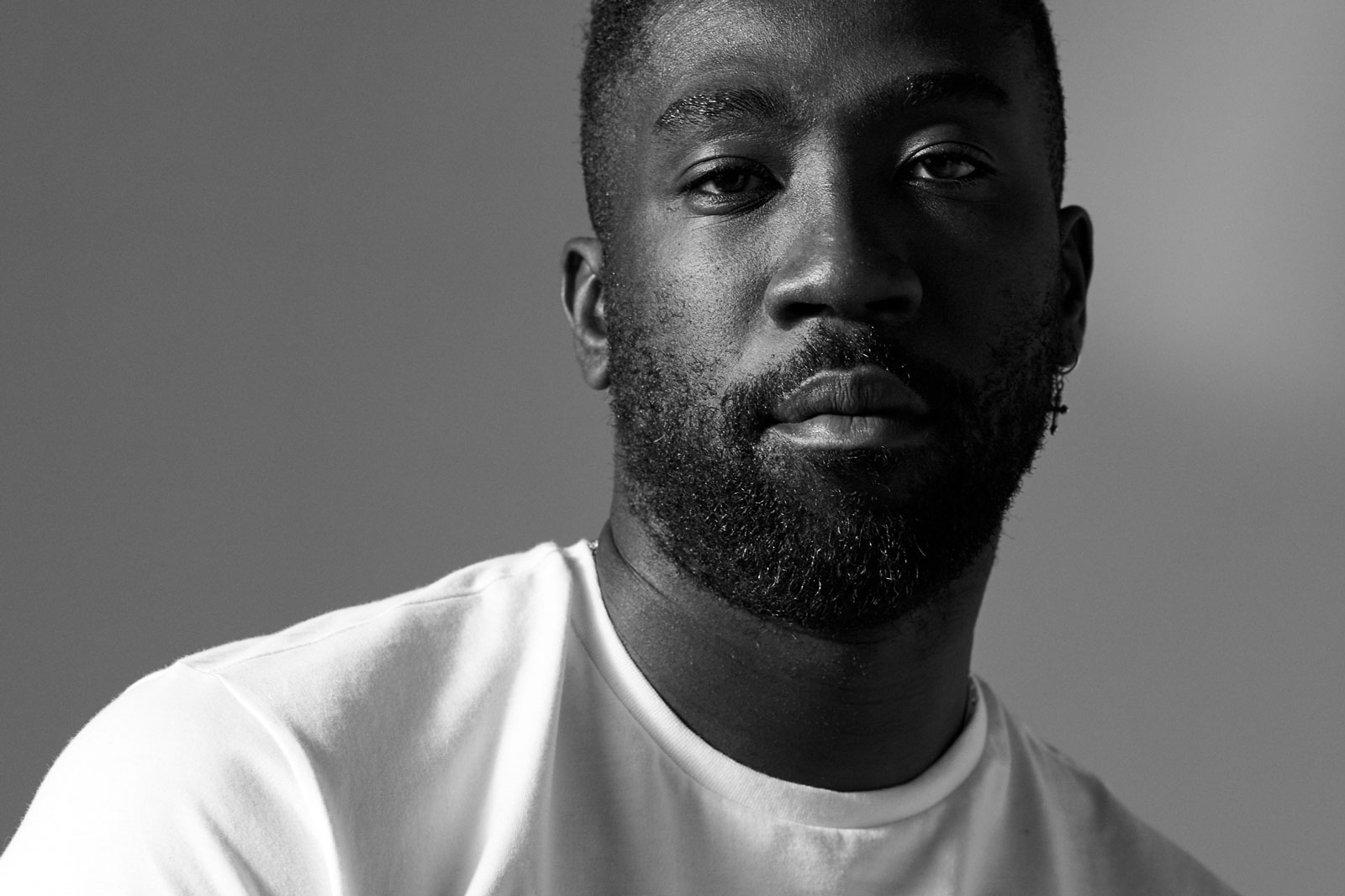

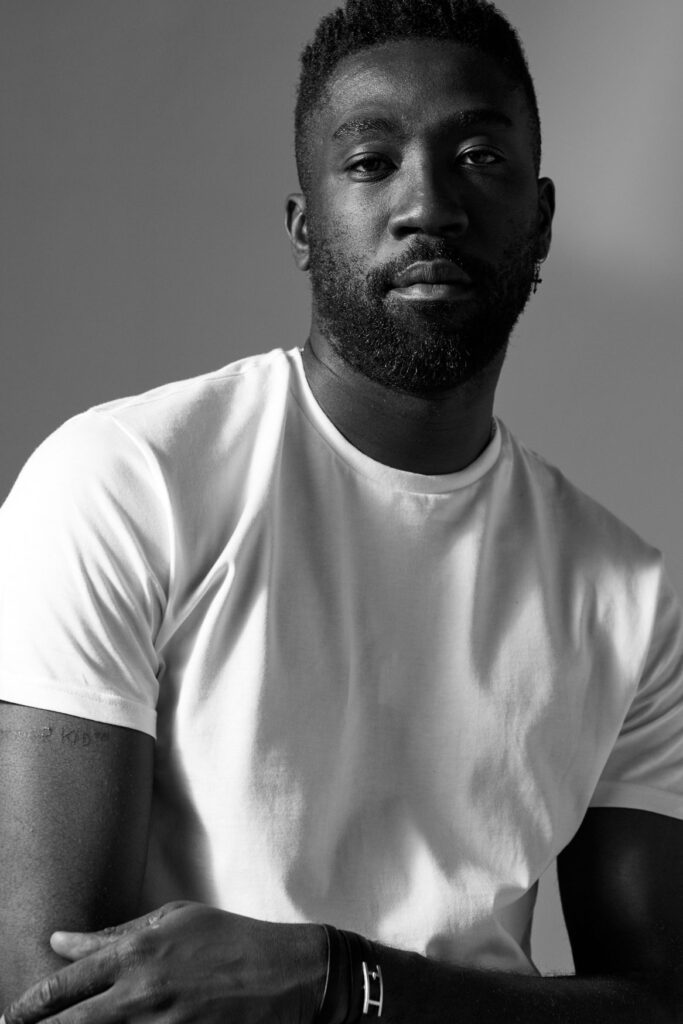

TQTB asks Camille Tanoh (he/him), CEO of New York-based The Proper Label™ about how he set up the ethical cornerstones of his brand.

TQTB: HEY CAMILLE, THANKS FOR SPEAKING WITH US. TELL US, WHEN DID YOU START THE PROPER LABEL™?

Camille Tanoh: The Proper Label™ is the organic evolution of The Proper Sneaker™. We launched The Proper Sneaker™ on 6th June 2014 – our everyday wear range The Proper Label™ followed on 16th July 2019.

YOU’VE BEEN IN THE FASHION INDUSTRY FOR A MINUTE. HOW HAS YOUR BACKGROUND IN THE INDUSTRY INFLUENCED YOUR DECISION TO START YOUR BRAND?

CT: After spending several years working for Balenciaga, and several fashion houses, I noticed the lack of inclusivity and transparency in the fashion industry. I felt that a company that would listen to customers and create more dialogue, accessibility and conversations, with a focus on product integrity, would have more chance of longevity than a company that solely focused on making non-essential clothes sold with the help of celebrity endorsements.

As an African man born in Paris, it’s always been difficult for me to witness the extravaganza of fashion weeks throughout the year. In addition, the success of fast fashion in Western countries in general, and the associated problems with landfill, air and water pollution in West Africa all played a part in finding a solution.

The Proper Label™ was born of my frustration with the excessive use of the world’s natural resources and the amount of waste produced by industrialised countries. We want to be an answer to the problem. If sustainability is a social class issue, then our mission is to democratise sustainability.

TQTB: THE RANGE FOCUSES ON HIGH QUALITY BASICS – WHY DID YOU OPT FOR EVERYDAY WEAR?

CT: The goal is to speak to the masses. The reach of a white tee and everyday wear clothing is larger than any expensive designer item.

TQTB: YOUR COMPANY IS FOUNDED ON A RIGOROUS SET OF STANDARDS. HOW DID YOU CREATE THEM?

CT: We created and trademarked our Supplier Code of Conduct after two years of research with an independent organisation modelled on similar principles to the Dutch Fairtrade foundation, Max Havelaar.

We developed The Proper Way™ – the idea is to design clothes using sustainable practices that results in a fair price composition between the consumer, manufacturer and business owner.

It also implies chasing ‘good profit’ and ‘principled entrepreneurship’. It helps to improve business practices while improving people’s lives.

TQTB: SO, WHAT’S THE PROCESS FROM SOURCING THROUGH TO PRODUCTION FOR ITEMS IN YOUR RANGES?

CT: Instead of starting with new materials, we design based on waste. Our responsibility in the design studio is to develop designs that last, anticipating the next use-cycle of each item.

We work with recycled materials provided by our sorting facility partners. If we’re not able to use recycled materials, we source the most sustainable materials possible. Our denim collection – soon to be released – is made from pre- and post-consumer recycled cotton, and recycled polyester from PET bottles. The typical take-make-use-waste cycle is the opposite of our mindset.

At The Proper Label™, we believe in using existing resources sustainably, manufacturing from recycled clothes. We actively encourage our customers to think about the next use of their items and ask them to dispose of them properly with us. We then recycle or repurpose the items so nothing goes to waste.

TQTB: THE RECYCLING ELEMENT IS AN EXTRA PIECE OF THE PRODUCTION CYCLE THAT, AS CONSUMERS, WE OFTEN DON’T REALISE CAN HAVE SUCH AN IMMEDIATE IMPACT ON THE PRODUCTION OF NEW ITEMS. WHAT KIND OF USES DO THESE RECYCLES MATERIALS GO INTO?

CT: Simply put, recycling is a necessity. The materials go into a range of uses – for example with our sneakers, we reuse the upper part to create new sneakers, while the rubber soles are repurposed into highway roads in Germany.

TQTB: WE’RE SEEING A GROWING NUMBER OF BRANDS ADOPT MORE SUSTAINABLE PRACTICES, FOR EXAMPLE, RECYCLED PLASTICS REPURPOSED INTO YARNS. ARE THERE ANY NEW INNOVATIONS IN SUSTAINABLE PRODUCTION THAT YOU’RE EXCITED TO SEE EVOLVE?

CT: Yes, all the alternatives to plastic are extremely interesting, but the issue again is not the material itself, but how we dispose of it. I hope that more brands will act to encourage consumers towards a more sustainable lifestyle.

Follow Camille: @theproperkid_

Follow The Proper Label™: @theproperlabel

IMAGE CREDITS:

Portrait photography: Neil F. Dawson